|

Title: Polyurethanes

polyurethane

Authors: Dr. Alireza Sedighizadeh - Sajjad Saberi Sarmur

Year of publication: Spring 1402

Abstract: Today it is very difficult to imagine a world without polyurethanes. Polyurethanes, despite their short history, have become one of the most dynamic groups of polymers. Currently, polyurethane chemistry has become an established technology worldwide in various industrial applications and covers practically all fields of application of polymers. Car seats, furniture, bedding, shoe soles, refrigerator and building thermal insulation, synthetic wood, various types of adhesives and coatings are just a few common examples of polyurethane in everyday life. Polyurethanes enable innovation and technological progress, helping to develop products that meet market needs and in many cases have been the key to implementing new technology.

|

|

|

Title: Scale Formation in Heat Exchangers

Scale Formation in Heat Exchangers

Authors: Mohammad Varnaseri-Seydmohsen Peyghamzadeh

Year of publication: 1403

Abstract: This book is a comprehensive collection of the authors' past experiences as well as a collection of the latest articles in the world that specifically address the issue of sedimentation of saturated solutions, especially calcium salts such as calcium carbonate and calcium sulfate. These salts are the most common sediment-forming agents in aqueous solutions that have inverse solubility and their solubility decreases with increasing temperature. Therefore, in heat exchangers where water is exposed to higher temperatures, these salts precipitate. This book is the result of years of practical and laboratory experience of its authors, although the results of studies by other researchers have also been comprehensively compiled in this book.

|

|

|

Title: Knowledge Management Nitric Acid Unit

Knowledge management Nitric acid unit

Authors: Ali Tahmasebi, Afshin Ghavami, Reza Salehi Original

Year of publication: 1401

Abstract: This scientific and practical booklet has been prepared and compiled based on scientific and practical expertise and experience for knowledge management and human resource training. In this collection, the history of problems that have arisen in the departments of the unit under different conditions and how to fix them to prevent them from recurring has been recorded. Also, site checks before commissioning, putting the unit into service and taking it out of service, increasing and decreasing capacity, analyzing laboratory results, and process instructions have been compiled in a concise and practical manner.

|

|

|

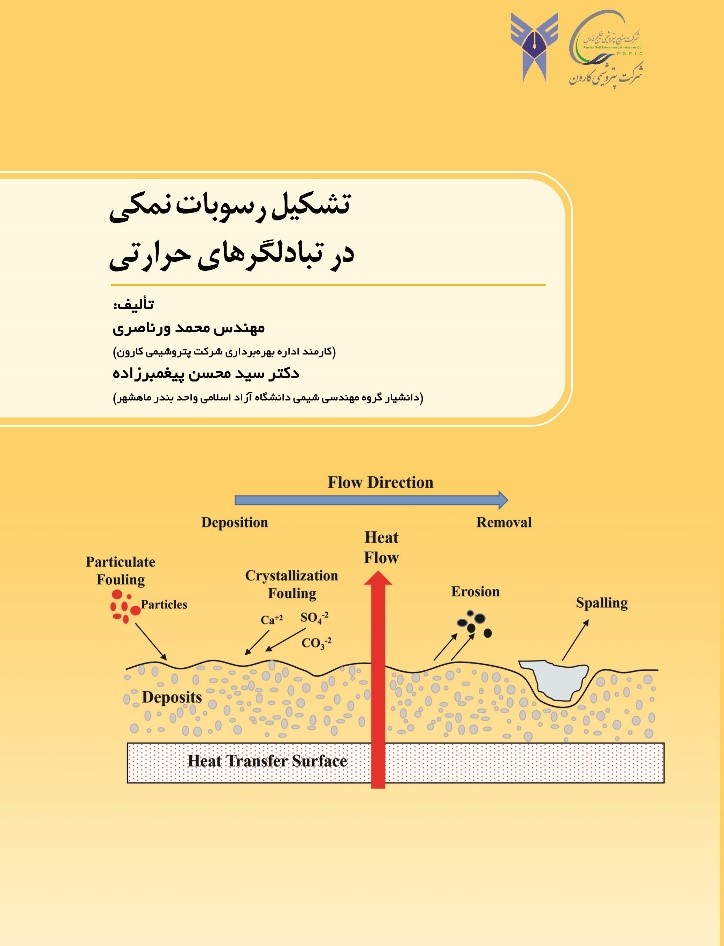

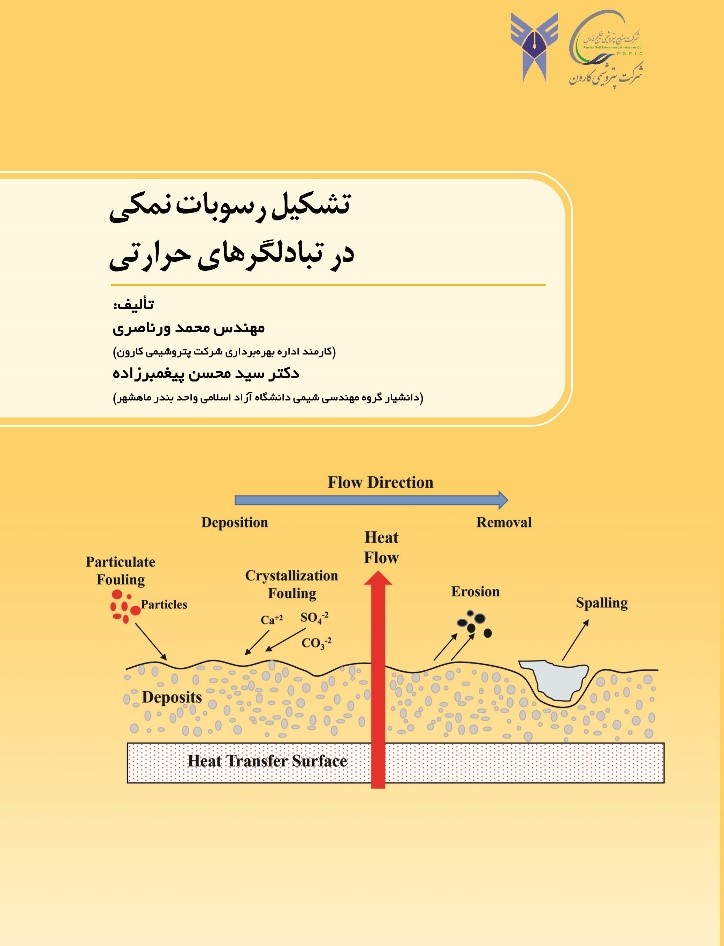

Title: Salt Fouling Formation in Heat Exchangers

Salts Fouling Formation in Heat Exchangers

Authors: Mohammad Varnaseri, Seyyed Mohsen Peybaghamzadeh

Year of Publication: 1401

Abstract: One of the operational problems that various industries are struggling with is the formation of scale in thermal equipment, which in addition to destroying and damaging the devices, plays a major role in wasting energy and its improper use. The scale layer formed on the surfaces of heat exchangers, due to the low conductivity coefficient and relative obstruction of the flow path, causes thermal resistance and additional pressure drop. As a result, the heat flux is reduced, the efficiency of the heat transfer device is reduced, and the power consumption increases. Since more than 90% of heat transfer equipment is exposed to scale formation, studying the mechanisms of scale formation, its prediction and control, and also estimating the economic losses caused by this phenomenon will be of great importance.

|

|

|

Title: Glass Lined Reactors (Operation, Maintenance and Repair)

Glass Lined Reactors

Authors: Saman Saki Yarahmadi

Year of Publication: 1401

Abstract: In the current century, due to the need to increase the diversity of various products in the fields of medicine, chemistry, agriculture, etc., the use of glass-lined equipment (steel equipment with glass coating) has been increasingly welcomed by manufacturers. In addition to the possibility of producing a variety of products, in many processes, if glass-lined equipment is not used, the production of some products cannot be cost-effective. Among the equipment that is made in glass-lined form are: chemical reactors, chemical towers, heat exchangers, storage tanks, pipes, etc., which, considering the importance of glass-lined reactors compared to other equipment, this equipment has been addressed more specifically.

|

|

|

Title: Polymeric diphenyl methyl diisocyanate plant operating manual

CDC and PMI Plant Operating Manual Polymeric di-phenyl Methyl Amine Plant

Authors: Hedayat Jafari, Alireza Abdolshahi, Mohammad Sasan, Alireza Khalaf Adeli

Year of publication: 1400

Abstract: PMI production is always carried out under the same process conditions, but depending on the PMA consumed in the two NOM and MOM models, the PMI production conditions will also change. If the PMA feed is prepared under normal operating conditions (NOM), the PMI product is sent to the PSM unit to produce different products or grades. If the PMA feed is prepared under modified operating conditions (MOM), the PMI product is stored directly in the CPMI LF tanks.

|

|

|

Title: Nitric Acid Plant Handbook

Nitric Acid Plant Handbook

Authors: Ali Tahmasebi, Shayan Shirali, Reza Salehi Original

Year of publication: 1400

Abstract: Ammonia is oxidized with air oxygen at a temperature of 921 degrees Celsius by passing through a platinum catalyst and then the main part of the reaction heat is recovered in heat exchangers. The oxidized process gases in the absorption tower react with water under high pressure and low temperature and are converted into nitric acid. Part of the reaction energy recovered in the heat exchangers is used to heat the tail gas and generate energy for the air compressor by means of the hot tail gas flow in the turbine.

|

|

|

Title: PMA Plant: Operating and Safety Manual

PMA Plant: Operating and Safety Manual

Authors: Gholamhossein Heydari, Reza Qanavati, Mohammad Reza Ebadi, Sina Jamali Davanizadeh

Year of publication: 2019

Abstract: Polymeric di-phenyl Methyl di-Amine (PMA) is produced by the continuous condensation reaction of aniline and formaldehyde in acidic media followed by rearrangement reaction. After neutralization and washing steps, the product is processed to remove water and excess aniline before is sent to an intermediate storage (PMA is purified for use in the PMI plant). The NaCl solution (brine) from the neutralization step is processed to completely remove organic materials

|

|

|

Title: Simulation and Design of Chemical Processes Using Aspen Hysys

Simulation and Design of Chemical Processes Using Aspen Hysys

Authors: Mohammad Varnaseri

Year of Publication: 2019

Abstract: This book contains tips and methods for simulating process equipment in the oil, gas, and petrochemical industries and is the result of the author's experience in teaching this software in universities and other scientific centers. It is the only simulation book that uses real industrial examples to teach simulation and explain the software's tips. The book includes a guide to determining thermodynamic models, defining hypothetical materials, simulating various types of thermal equipment, pressure change equipment, various types of chemical reactors, various types of towers, various types of solids separation equipment, logical equipment, and electrolyte environment equipment. Also, examples available in the software and other books available on the market have been used to fully explain the tips.

|

|

|

Title: Operating Manual Polymeric di-phenyl Methyl Amine Plant

Operating Manual Polymeric di-phenyl Methyl Amine Plant

Authors: Gholamhossein Heidari, Reza Qanavati, Mohammad Reza Ebadi, Sina Jamali Davanizadeh

Year of Publication: 2019

Abstract: Polymeric diphenyl methyl amine is produced by a continuous condensation reaction between aniline and formaldehyde in an acidic medium followed by a rearrangement reaction. After neutralization and washing steps, the product enters the purification stage to remove excess water and aniline before being sent to intermediate tanks. The brine solution is processed from the neutralization stage to the complete removal of organic compounds.

|

|

|

Title: TDI Unit Safety Handbook

TDI Plant Safety Handbook

Authors: Maziar Sharifpour

Year of publication: 2018

Summary: Most accidents can be prevented by taking simple measures or adopting proper working procedures. This handbook is intended to outline important issues on safety and health that should be paid attention to on KRNPC for easy reference by the workers. If we work carefully and take appropriate safety measures, there will definitely be fewer work injury cases, and our site will become a safe and secure place to work in. This employee safety handbook has been collected to provide employees with health and safety information. It also includes information about your duties as an employee and will help you understand health and safety issues that affect you at work.

|

|

|

Title: Nitrobenzene Unit Safety and Operation Manual (Volume 1 and 2)

NITROBENZENE: Operating and Safety Manual (Part 1,2)

Authors: Ahmad Hossein Nejad, Mehrdad Mohammadian

Year of Publication: 2018

Abstract: Nitrobenzene is an organic compound with chemical formula C6H5-NO2. It is water-insoluble pale yellow oil with an almond-like odor. It freezes to give greenish-yellow crystals. It is produced on a large scale from benzene as a precursor to aniline. In the laboratory, it is occasionally used as a solvent, especially for electrophilic reagents.

|

|

|

Title: Study of Side Reactions Leading to Color Formation in a Polyurethane Production Chain

Study the Investigation of a Side Reaction Leading to Color Formation in a Polyurethane Production Chain

Authors: Sajjad Saberi Sarmur, Hamed Gharehdagi

Year of Publication: 2018

Abstract: One of the well-known characteristics of aromatic isocyanates is that polyurethanes produced from them turn yellow rapidly when exposed to light or heat; while aliphatic isocyanates produce more stable products. In fact, polyurethanes produced from MDI are the most unstable. In this book, the cause of this coloration is investigated and it seems that this happens through a radical mechanism. The general scheme of this reaction was proposed by Twitchett and the proposed reaction involves urea compounds that are initiated by the reaction of the isocyanate product with an amine.

|

|

|

Title: Aniline Unit Safety and Operation Manual

ANILINE: Operating and Safety Manual

Authors: Ahmad Hossein Nejad, Mehrdad Mohammadian

Year of Publication: 2018

Abstract: Aniline is an organic compound with the formula C6H5-NH2. Consisting of a phenyl group attached to an amino group, aniline is the prototypical aromatic amine. Its main use is in the manufacture of precursors to polyurethane and other industrial chemicals. Like most volatile amines, it has the odor of rotten fish. It ignites readily, burning with a smoky flame characteristic compounds

|

|

|

Title: ANILINE AND NITROBENZENE HANDBOOK

ANILINE AND NITROBENZENE HANDBOOK

Authors: Ahmad Hossein Nejad, Ehsam Shirmardi, Mahmoud Amiri, Reza Shalibi, Omid Varksha

Year of publication: 2018

Abstract: Abstract: Nitrobenzene is an organic compound with chemical formula C6H5-NO2. It is water-insoluble pale yellow oil with an almond-like odor. It freezes to give greenish-yellow crystals. It is produced on a large scale from benzene as a precursor to aniline. In the laboratory, it is occasionally used as a solvent, especially for electrophilic reagents. Aniline is an organic compound with the formula C6H5-NH2. Consisting of a phenyl group attached to an amino group, aniline is the prototypical aromatic amine. Its main use is in the manufacture of precursors to polyurethane and other industrial chemicals. Like most volatile amines, it has the odor of rotten fish. It ignites readily, burning with a smoky flame characteristic compounds

|

|